- info@ficci.org.bd

- |

- +8802222271610, +8802222271611

- Contact Us

- |

- Become a Member

- |

- |

- |

- |

- |

Preface: Running Out of Time

I was recently reading the Bangladesh Country Environment Analysis and I must say it left me perturbed to say the least. To quote the report, “In Bangladesh, the exposure to environmental health risk factors is at critically high levels. Four major environmental health risks were associated with over 272,000 premature deaths and 5.2 billion days lived with illness, which has an annual cost equivalent to 17.6 percent of GDP in 2019.” As we breach the 1.5°mark1, we are running out of time and without urgent action, including further adaptation and resilience measures, the country's robust growth potential could be in risk.

Green Growth: Digging Ourselves Out

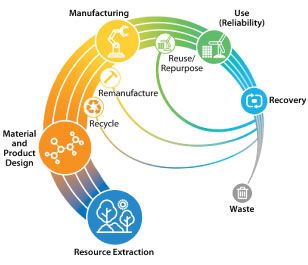

Mid-June, I was at the launch of World Bank's Framework for Implementing Green Growth for Bangladesh. The framework elucidates that by balancing economic prosperity with environmental compliance, benefits, and protec-tion-can be a strong and sustainable driver of growth. As the Bank's Country Director says “Global experience shows that growth that harms the environment cannot be sustained. On the other hand, green growth can offer a strong and effective way to reduce poverty while safeguarding our environment, essentially serving as a catalyst for growth." I am a big advocate of this. From a business perspective green growth can only come when we see if from the perspective of a Green Value Chain Development which is a systemic approach, which integrates environmental support functions, environmental rules and regulations, and market players. It transforms the conventional linear view of value chains into a cyclical system view in which value chains operate in the natural environment on which they depend and which they also affect. Green value chains can also help to improve social welfare by providing better working conditions for employees and by supporting local communities.

Green value chains are important for industries for several reasons, including:

• Environmental benefits: Green value chains can help to reduce the environmental impact of an industry, by minimizing waste, using more sustainable materials, and reducing energy consumption. This can help to improve air quality, protect water resources, and mitigate climate change.

• Economic benefits: It can also create new  economic opportunities, as businesses develop new products and services that are more sustainable. This can lead to job creation, increased investment, and a more competitive economy.

economic opportunities, as businesses develop new products and services that are more sustainable. This can lead to job creation, increased investment, and a more competitive economy.

• Social benefits: It can also improve social welfare, by providing better working conditions for employees and by supporting local communities. This can lead to a more equitable and sustainable society.

The manufacturing industry is making progress in adopting green value chains. For example, many manufacturers are now using energy-efficient equipment, recycling materials, and designing products that are easier to repair and recycle.

Palm Oil: A Compelling Case Study of When Green and Economics Meet

Soaps are an important category in Bangladesh market for providing consumers with a means for daily personal hygiene. Toilet soap market makes up around 95% of the soap bars market because it provides an affordable option for consumers. The size of Toilet Soap market in Bangladesh is approximately 65,000-70,000 metric tons (MT) annually.

A minimum 70% Total Fatty Matter (TFM) has been mandated for manufacturing toilet soap.

The oils required for manufacturing Toilet Soaps are from Palm trees, and the increasing demand for palm oils have in the past contributed to widespread cases of deforestation in the world. The palm oil deforestation map covers the rainforests of Southeast Asia, Latin America, and West Africa, bringing negative consequences for tropical wildlife and our planet in general. Palm oil cultivation and production also contributes to global warming by increasing greenhouse gas (GHG) emissions due to carbon release, particularly, after slash-and-burn practices, reduces soil health and adds to water pollution.

Oils and soap noodles are required for manufacturing Toilet Soap are highly import dependent. For context, every year a total of approximately 30,000 MT Crude Palm Kernel Oil and RBD Palm Stearin including approximately 22,000 MT of soap noodles are being imported in Bangladesh annually for that purpose. However, globally the soap industry has gone through an evolution, and it is feasible to produce an excellent quality soap bar with no more than 40% TFM and in some cases even less. Further, due to lower amount of fatty matter going down the drain, the impact on wastewater treatment is reduced as well.

Regulatory reforms that are in line with science and technological developments can help to reduce the dependency on oils /TFM for making soap and will ensure tremendous environmental and fiscal benefits for Bangladesh.

Components of Green Value Chain: Enabler for Green Economy

Green Value Chain Development is a systemic approach and can be divided into 3 distinct buckets.

1. Sustainable Sourcing

Sustainable sourcing is critical across all industries. The goal of sustainable sourcing is to build strong, long-term relation- ships with suppliers. Improving performance on environmental, social, and ethical issues is vital to developing such relationships. Working toward this has become an extension of a company's commitment to corporate responsibility and, as such, a key component of the overall business structure and model.

Key measures under sustainable sourcing for FMCG company

• Sourcing of raw/agricultural material

• Sourcing of Packaging material

Sourcing of paper-based office material

Relationship of sustainable sourcing with SDG -

• SDG 13: Climate Action by reducing greenhouse gas emissions, deforestation, and resource extraction.

• SDG 14: Life Below Water by protecting marine ecosystems and conserving marine life.

• SDG 15: Life on Land by safeguarding terrestrial ecosystems and biodiversity.

Government Recognition, Benefits, and Incentives to promote sustainable sourcing -

• Industry can get duty benefit and express service in customs during releasing of raw materials and packaging materi-als which will be sourced from sustainable sourcing.

2. Sustainable Production and Consumption

Sustainable production and consumption can be defined as production and use of products and services in a manner that is socially beneficial, economically viable and environmentally benign over their whole life cycle.

Key measures under sustainable production and consumption for FMCG company -

• Using of renewable energy source

• Reducing Carbon emissions

• Waste reduction

• Water savings

• Introducing of ETP

Relationship of sustainable production and consumption with SDG-

• SDG 6: Clean Water and Sanitation by reducing water pollution, introducing ETP and promoting responsible water use, water-intensive products and supporting water conservation initiatives.

• SDG 7: Affordable and Clean energy by encouraging the use of clean and renewable energy sources. Industries adopting energy-efficient technologies and renewable energy solutions.

• SDG 12: Responsible Production and Consumption by focusing on minimizing resource extraction, waste generation, and environmental impacts.

• SDG 13: Climate Action by adopting low-carbon and resource-efficient manufacturing processes.

• SDG 14: Life Below Water by reducing plastic usage, promoting sustainable seafood consumption, and reducing pollution.

• SDG 15: Life on Land by promoting sustainable consumption habits, fostering a more sustainable relationship with nature.

Government Recognition, Benefits, and Incentives to promote sustainable sourcing -

• VAT structure for products produced under components "Sustainable production and consumption" can be more beneficiary compared to regular products.

3. Waste Management and Plastic Circularity

Waste management is where we close the loop; we must reuse and recycle as much waste as we can so that it can re-enter the economy rather than sitting in a landfill or littering the environment.

Key measures under Waste Management and Plastic Circularity for FMCG company-

• Recycle, re-use or co-process of waste which gets produced during production.

• Introducing of SWM program

• Reduction of virgin plastics

• Using of recycled plastics

• Using of reusable, recyclable, or compostable plastics

• Collection and process of plastics

Relationship of Waste Management and

Plastic Circularity with SDG -

• SDG 6: Clean Water and Sanitation

• SDG 9: Industry, Innovation, and Infrastructure

• SDG 11: Sustainable Cities and Communities

• SDG 12: Responsible Consumption and Production

• SDG 13: Climate Action

• SDG 14: Life Below Water

• SDG 15: Life on Land

Government Recognition, Benefits, and Incentives to promote sustainable sourcing -

• Corporate Tax can be lower for industry who introduced "Waste Management and Plastic Circularity" in their value chain initiatives.

Components of Green Value Chain: Enabler for Green Economy

Government can introduce a certification process for industry who are implementing green value chain initiatives in their business. Different dynamic ratings (A+, A, B+, B etc.) can be given by government authorities in certification based on the performance of the industry.

Government Recognition, Benefits, and Incentives to promote green value chain initiatives.

• Government can introduce annual award for industry as a recognition of best practices.

•Top management Chair/CEO of such industry can get special entitlement like CIP.

•Industry can use their certification for commercial purpose.

•EPB can provide special and express support to facilitate export of products which are produced under green value chain.

•Industry can get duty benefit and express service in customs during releasing of capital machineries, raw materials and packaging materials which will be imported for either install green value chain initiatives or produce products under green value chain.

•VAT structure for products produced under green value chain can be more beneficiary compared to regular products.

•Corporate Tax can be lower for industry who introduced green value chain initiatives.

•Loan with lower interest rate can be given to industry to initiate green value chain in the business process.

Post Face: What Needs to be Done

As I had mentioned at the beginning of the article, we are running against time. It is now time to create concrete steps that helps us to take decisive actions to accelerate the 'Green Growth' to business a sustainable business for s smart and sustainable Bangladesh.

• Policy Framework: Leverage other trade chambers and Build platform to conduct private sector dialogues on green value chain policy construct, policies, and reforms with GoB. Proposed Responsibility: FICCI, BIDA & BUILD

• Building Competitive Advantage in the Business Model: Introduce financial measures, incentives, and capability integration to build competitive edge through GVC, especially for MSMEs. Proposed Responsibility: FICCI, BIDA & DCCI

• Human Capital Development: Facilitate human capital development through awareness building, knowledge sharing, and youth partnership. Proposed Responsibility: UNDP, World Bank & ADB

• Research & Development: Academia, private sector, and public sector partnership to build deeper understanding and knowledge on GVC. Proposed Responsibility: UNEP & UNDP

• Reporting: Voluntary reporting of existing GVC initiative into the SDG tracker. Proposed Responsibility: FICCI & A2i